Ingersoll Rand CAMERON COOPER Nx Series Cooler Air Cooler Water Cooler Inter Cooler After Cooler Cooler Core Cooler Bundle

From installation throughout the entire lifecycle of the compressor, Ingersoll Rand's MSG TURBO-AIR NX series centrifugal compressor is designed to meet your needs with industry-leading features

- HaoLin

- China

- Information

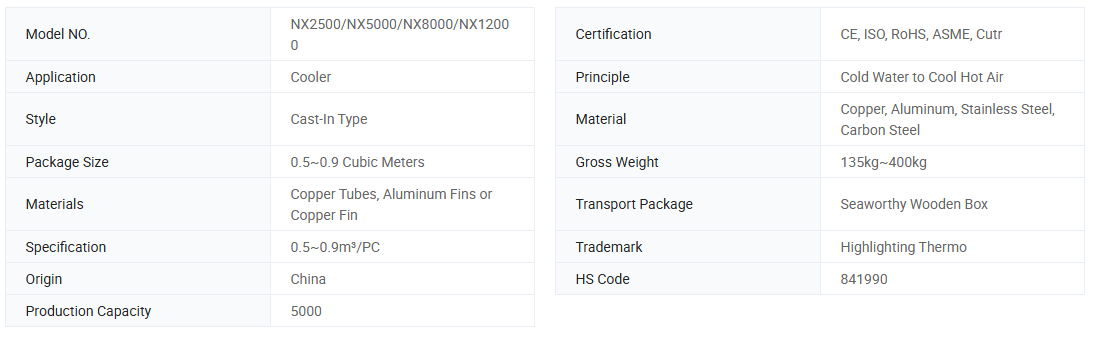

Basic Info.

Product Description

Product Highlights

From installation throughout the entire lifecycle of the compressor, Ingersoll Rand's MSG TURBO-AIR NX series centrifugal compressor is designed to meet your needs with industry-leading features, including:

Highly efficient aerodynamic components (inlets, impellers, scrolls and diffusers) combined with low mechanical losses and power conserving inlet throttle control (IGV) provide up to 5% better specific power than competitive models.

Integrated structural base provides a foundation for the main driver and serves as a support platform for the side-mounted lube system/reservoir

Side-mounted lube reservoir with top-mounted components and standard duplex filters ease maintenance requirements and provide continuous, uninterrupted operation.

Gearbox inspection covers offer simple accessibility for quick field inspection and onsite assessment of rotating assembly health.

Split pinion bearing and seal design allows for easy onsite inspection.

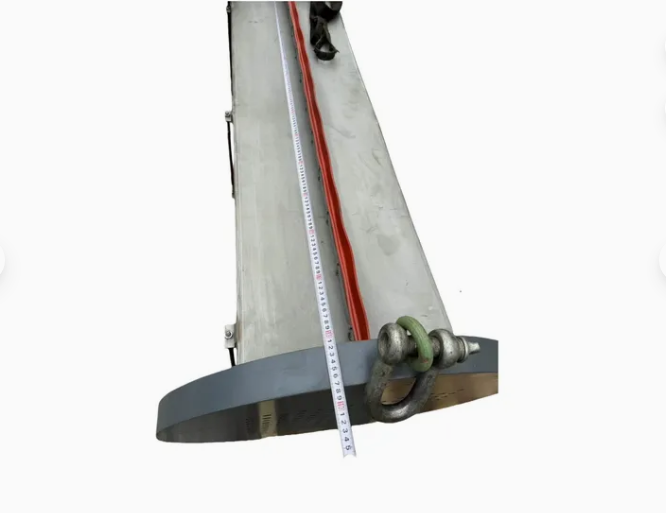

Next generation intercoolers are optimized for specific flow and pressure requirements and include a straight tube design that is roddable-in-place

Easily accessible dual condensate connections (two connections for each cooler) simplifies maintenance and reduces onsite piping and installation

OEM-optimized cast-in water manifold, with provisions for optional patent-pending integral trim valves all tied together at a single-point customer water connection

Expertly optimized stage and gas passages utilizing computational fluid dynamics (CFD)

| NX SERIES AIR COMPRESSORS | OTHER COMPRESSORS |

| Compression elements do not wear or require periodicreplacement Oil filter elements are easily replaced Bearings designed for extended life | Require regular maintenance and periodic replacementof air ends Result in high operating expenses and significant machinedowntime |

| 100% oil-free per 150 8573-1 certification Prevent contamination of system | Contacting compression elements are subject to wearLimited rotating element life Designed-in wearng items to generate aftermarket revenues |

| Centrifugal compressors are proven to have a long meantime between failures (MTBF), and independent researchhas shown an industry-leading availability of 99.7% Conservative high-quality gear design | Contacting compression elements are subject to wear Limited rotating element life Designed-in wearng items to generate aftermarket revenues |

| Automatic operation for any operating condition State-of-the-art MAESTRO suite of controls PLC control available | Limited control capability Costly, high-maintenance variable speed configurations |

| Essentially vibration-free No spedal foundation is required | Special foundations needed to handle heavy weight Precautions must be taken to prevent transmission of vibrationto other equipment |

Air cooler(inter cooler and after cooler) matched with Ingersoll Rand(Cameron) centrifugal air compressor NX2500/NX5000/NX8000/NX12000.

Materials: copper or stainless steel tubes with aluminum fins or copper fins. the fins can be pure aluminum/copper, or phenolic resin coated fins which is more durable