Atlas Copco Oil Free Rotary Screw Air Compressor Air Cooler Water Cooler

- HaoLin

- China

- Information

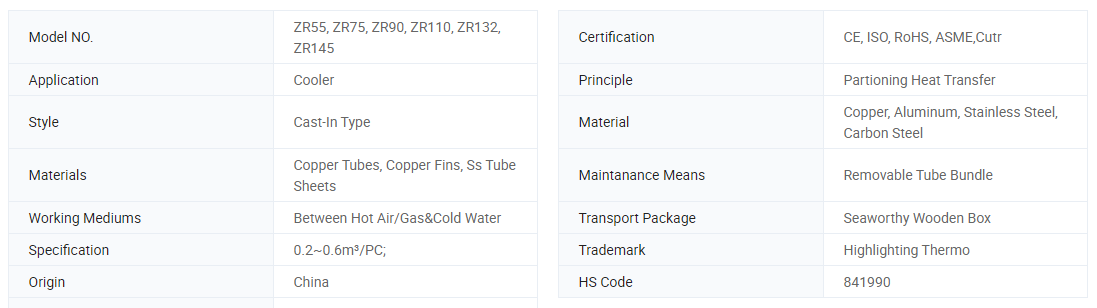

Basic Info.

Product Description

The best of all worlds

The shortest route to superior productivity is to minimize operational cost while maintaining anuninterrupted supply of the right quality of air. The Atlas Copco Z compressor series is focused oneffectively saving energy, ensuring product safety - only oil-free machines exclude contamination risks100% - and guaranteeing the utmost reliability around the clock. And not just today, but day after day,year after year, with minimal maintenance cost, few service interventions and long overhaul intervals

Highest reliability

Highest reliability

For over 60 years Atlas Copcohas pioneered the developmentof oil-free air technologyresulting in the largest range ofair compressors and blowerswithin our industry.

The most completepackage

With the ZR/ZT compressor,Atlas Copco provides a totallyintegrated, ready-to-use

package including internalpiping, coolers, motor.

lubrication and control system.

100% oil-freecompressed air

The ZR/ZT offers you 100% pure,clean air that complies with lSO8573-1 CLASS 0 (2010)certification.

Global presence -local service

Our aftermarket product

portfolio adds maximum value

by ensuring optimum

availability and reliability of

compressed air equipment with

the lowest possible operating costs.

Maximum energyefficiency

The ZR/ZT's superior oil-freescrew elements provide theoptimum combination of highFree Air Delivery (FAD) with thelowest energy consumption.

SMARTLINK

Monitor your compressed airinstallation with SMARTLINKKnowing the status of yourcompressed air equipment at alltimes is the surest way to

achieve optimal efficiency andmaximum availability.

Features & benefits

Introducing the Atlas Copco ZR/ZT 200-355 VSD+, where eficiency meets reliability and sustainability.

This air compressor is designed for industries demanding high compressed air quality standards.

Efficient motor

Permanent Magnet water cooled motor with oil lubricatedbearings.

Rock-solid reliability prevents dust and water entering themotor.

NEos drive

Atlas Copco NEOS inverter is designed to work in the harshconditions of the compressor house.Modular design allows replacement ofindividual components,reducing maintenance cost.The cubicle keeps the inverter cool extending the lifetime &increasing operational efficiency.

Zero loss drains

Clearance of all water & contamination.

Increasing both product & system reliability

Easy access

Easy access to all components to minimize maintenance timesHinged doors for easy routine maintenance eg.cleaning.Saves valuable and often expensive floor space in a facilityHighest ratio flow/footprint on the market.

Soundproof design

Silenced canopy ensures optimal working conditions foreveryone in theimmediate environment.Optimized internal ducting and integrated pulsation damper toreduce the noise level.

High quality coated canopy to prevent dust.

Grouped service items

Minimal service time because service parts are grouped togetherfor ease of access.

All components are designed for serviceability and long lastinglifetime.

Integrated dryer

Having an integrated dryer helps for easier installation, lesspressure drop because of more efficient connectionsOn top of that it also saves a lot ofspace in your compressorroom.

The shortest route to superior productivity is to minimize operational cost while maintaining anuninterrupted supply of the right quality of air. The Atlas Copco Z compressor series is focused oneffectively saving energy, ensuring product safety - only oil-free machines exclude contamination risks100% - and guaranteeing the utmost reliability around the clock. And not just today, but day after day,year after year, with minimal maintenance cost, few service interventions and long overhaul intervals

Highest reliability

Highest reliabilityFor over 60 years Atlas Copcohas pioneered the developmentof oil-free air technologyresulting in the largest range ofair compressors and blowerswithin our industry.

The most completepackage

With the ZR/ZT compressor,Atlas Copco provides a totallyintegrated, ready-to-use

package including internalpiping, coolers, motor.

lubrication and control system.

100% oil-freecompressed air

The ZR/ZT offers you 100% pure,clean air that complies with lSO8573-1 CLASS 0 (2010)certification.

Global presence -local service

Our aftermarket product

portfolio adds maximum value

by ensuring optimum

availability and reliability of

compressed air equipment with

the lowest possible operating costs.

Maximum energyefficiency

The ZR/ZT's superior oil-freescrew elements provide theoptimum combination of highFree Air Delivery (FAD) with thelowest energy consumption.

SMARTLINK

Monitor your compressed airinstallation with SMARTLINKKnowing the status of yourcompressed air equipment at alltimes is the surest way to

achieve optimal efficiency andmaximum availability.

Features & benefits

Introducing the Atlas Copco ZR/ZT 200-355 VSD+, where eficiency meets reliability and sustainability.

This air compressor is designed for industries demanding high compressed air quality standards.

High performance elements

Next generation world class compression element.Atlas Copco superior rotor coating for high durability.Thermal efficiency reduces the expansion leading to reducedwear and increased reliability.More compact, improved rotor profiles and coolingjackets formaximum durability.

Advanced touch screen monitoring system

User-friendly Elektronikone Touch, with enhanced connectivitypotential.Included warningindications, maintenance scheduling andonline visualization of the machine's condition forincreasedreliability.Efficient motor

Permanent Magnet water cooled motor with oil lubricatedbearings.

Rock-solid reliability prevents dust and water entering themotor.

NEos drive

Atlas Copco NEOS inverter is designed to work in the harshconditions of the compressor house.Modular design allows replacement ofindividual components,reducing maintenance cost.The cubicle keeps the inverter cool extending the lifetime &increasing operational efficiency.

Reliable cooling

Cooler with highly efficient water separator for higher reliabilityStainless steel enlarged surface coolers to ensure topperformance over a long lifetime.Pipes with star profile form bi-anodised aluminium forpreventing corrosionEasily removable for quick, cost-efficient maintenance.Zero loss drains

Clearance of all water & contamination.

Increasing both product & system reliability

Easy access

Easy access to all components to minimize maintenance timesHinged doors for easy routine maintenance eg.cleaning.Saves valuable and often expensive floor space in a facilityHighest ratio flow/footprint on the market.

Soundproof design

Silenced canopy ensures optimal working conditions foreveryone in theimmediate environment.Optimized internal ducting and integrated pulsation damper toreduce the noise level.

High quality coated canopy to prevent dust.

Grouped service items

Minimal service time because service parts are grouped togetherfor ease of access.

All components are designed for serviceability and long lastinglifetime.

Integrated dryer

Having an integrated dryer helps for easier installation, lesspressure drop because of more efficient connectionsOn top of that it also saves a lot ofspace in your compressorroom.

Get the latest price? We'll respond as soon as possible(within 12 hours)