Atlas Copco Oil-Injected Rotary Screwcompressors Oil Cooler Ga Series

- HaoLin

- China

- Information

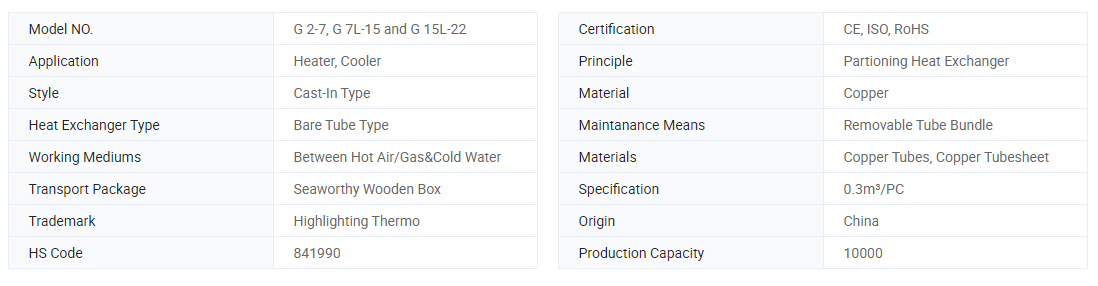

Basic Info.

Product Description

Highest reliability,lowest operating costs

The shortest route to maximize your profitability is to minimize your

operational costs. With up to 80% of a compressor lifecycle cost

coming from the energy it consumes, this should be a clear focus.

Atlas Copco's GA compressors with SmartInjection enabled

compression elements and IE4 or better class motors are designed to

achieve significant energy savings while providing long and troublefree

life even in the harshest environmental conditions.

Efficiency

At the heart of the GA compressors are state-of-the-artcompression elements with Smartinjection technology and highefficiency oil cooled lE4 or better class motors. This highlyefficient drive train coupled with generous cooling capacity, lowinternal pressure drops and precise control from theElektronikon@ Touch ensures optimum efficiency.

Reliability

The GA compressor's drive train is lP66 rated protecting itcompletely from environmental dust and moisture ensuring it canoperate reliably in the toughest conditions and at ambienttemperatures up to 55°C/131°F

Serviceability

Service time is reduced to a minimum with all service partsgrouped together for ease of access and, if greater assess isrequired, the patented portal design enables full access to allcomponents. Each component has also been designed forserviceability, halving the time required to service compared totraditional designs.

Get the latest price? We'll respond as soon as possible(within 12 hours)